Diesel Technology

Beside the continuous development, the Injection Pump Center of Móricz Kft. intends to fill every requirement of the domestic and international standards, and meet the demands of its customers and partners. We focus our attention on the changes of diesel technology, and pay heightened attention to improve the professional knowledge of our colleagues. It is our strategic aim to be adapted for the international expectations and meet the demands of our customers.

Our workshop is equipped with the most modern Bosch and Hartridge diesel test benches. All together we have 10 test benches.

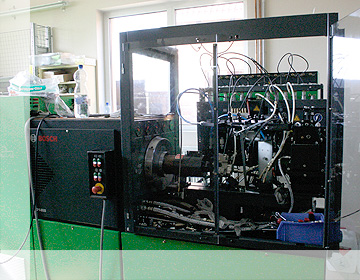

BOSCH EPS 815 diesel test bench

type of the injection pump

- CP-1

- CP-2

- CP-3

- CR injector

- PIEZZO injector

The injection pressures on which modern Common-Rail diesel engines run have risen constantly over the last few years. 2000 bar is nowadays already normal – with a rising tendency. Our new diesel test bench EPS 815 from Bosch specially for Common Rail injection pumps and injectors therefore enables testing with up to 2200 bar. Its newly developed rail is designed for pressures up to 2500 bar, which means that the test bench is prepared for future developments in diesel technology.

BOSCH EPS 815 diesel test bench

type of the injection pump

- VP30

- VP44

The new type test bench of Bosch is operated with computer, and has a 15 KW capacity direct drive. The test bench doesn't have accessories sets, but the expansion is possible with different retrofit kits and special accessories sets. It can be equipped with two different measuring systems: measuring glass technology for conventional diesel injection pumps or KMA system for continuous fuel delivery analysis.

BOSCH EPS 815 diesel test bench

type of the injection pump

- CP-1

- CP-2

- CP-3

- CR injector

- EUI

- PLD

The new type test bench of Bosch is operated with computer, and has a 15 KW capacity direct drive. The test bench doesn't have accessories sets, but the expansion is possible with different retrofit kits and special accessories sets. It can be equipped with two different measuring systems: measuring glass technology for conventional diesel injection pumps or KMA system for continuous fuel delivery analysis.

BOSCH EPS 708 diesel test bench

type of the injection pump

- CP-1

- CP-3

- CP-4

- CR INJECTOR

The injection pressures on which modern Common-Rail diesel engines run have risen constantly over the last few years. 2000 bar is nowadays already normal – with a rising tendency. The new diesel test bench EPS 708 from Bosch specially for Common Rail injection pumps and injectors therefore enables testing with up to 2200 bar. Its newly developed rail is designed for pressures up to 2500 bar, which means that the test bench is prepared for future developments in diesel technology.

BOSCH EPS 200 diesel test bench

type of the injection pump

- CRI/CRIN

- CRI and other manufacturers

Bosch EPS 200 is an automatic diesel injection pump testing equipment for Common Rail and Unit injectors, which allows quantity measurement with test specifications. This compact workshop tester has an intuitive user interface with touch screen operation. This test bench is computer operated. It has an excellent economy through automatic test sequence, which is documented by the machine. It has an integrated database for filing test specifications and customer data.

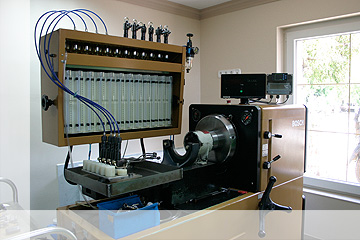

HARTRIDGE AVM 10-8 test bench

type of the injection pump

- STANADYNE

- DB2

- DB4

- DE10

- Target

- ZEXEL

- VE

- EDC

- EDC - with ROM-module (Covec-F)

- VRZ - with ROM-module

- DELPHI

- DPA

- DPC

- DPS

- DPCN

- DP200

- DP210

- DP310

HARTRIDGE AVM test bench is made in England, and has a 15 KW drive capacity and 8 cylinders for continuous fuel delivery analysis. The injection pump is driven directly from the axle of the electric motor with the help of its clutch. The test bench can be operated with the keyboard under the TFT display.

HARTRIDGE CRi-PC test bench

type of the injection pump

- control, repair and programming of Delphi injectors with factory technology

The CRi-PC test bench has been designed to test pressure-holding injectors. It can be used for injectors distributed by Bosch, Delphi, Denso and Siemens. The test bench can be extended with different modular kits.

HARTRIDGE CRp-PC test bench

type of the injection pump

- Delphi high-pressure injection pump

- Siemens high-pressure injection pump

- Denso high-pressure injection pump

The CRp-PC with auto pressure control, test speeds of up to 6500rpm and a future upgrade path to 3000bar test pressures provides testing of all makes of common rail pumps quickly and simply, thus increasing the available time on other test platforms – providing additional business opportunities and improving workflow.

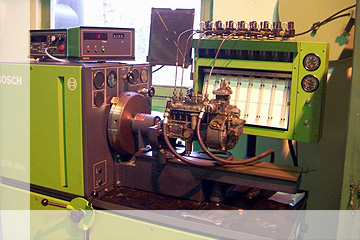

BOSCH EFEP 515 test bench (2 pieces)

type of the injection pump

- BOSCH

- VA

- VE

- VE TURBO

- VE EDC

- A

- MW

- P-mechanical in-line

- P-EDC-in-line

- H-EDC-in-line

BOSCH EPS 604 test bench

type of the injection pump

- for smaller rotary injection pumps

This test bench is made for smaller rotary mechanical diesel injection pumps, also for testing and adjusting their controllers and control gears. The electric motor, the hydrostatic transmission, the two-stage gearbox and the fuel injection pump are all assembled on the same frame. The overflow-fuel quantity measurement equipment is rotatable and can be set vertically. The speed of the driving motor can be continuously seen on a four-digit display.